If you look around the room you are sitting in right now, almost every object you see—from the chair beneath you to the device in your hand—has been on a journey. It has crossed oceans, traversed highways, and moved through warehouses.

This movement is not magic; it is the result of logistics and transport.

While often used interchangeably, these two terms represent distinct functions. Understanding the difference is crucial for anyone entering the business world, managing a supply chain, or simply curious about how the global economy functions. This guide will dismantle the complexities of logistics and transport, explaining how they function as the “brain” and “muscle” of trade.

Table of Contents

- The Core Distinction: Logistics vs. Transport

- What is Transport? (The Muscle)

- What is Logistics? (The Brain)

- The 7 Rs of Logistics

- Key Differences at a Glance

- How They Work Together

- The Future of the Industry

The Core Distinction: Logistics vs. Transport

To put it simply: Transport is the movement of things, while logistics is the management of that movement.

Think of a taxi service.

- Transport is the car driving the passenger from Point A to Point B.

- Logistics is the app algorithm that routes the nearest driver to you, calculates the ETA, processes the payment, and ensures the car has fuel and maintenance.

Transport executes the action; logistics plans, optimizes, and manages the flow.

This overlap is precisely why many industry providers explicitly combine the terms in their branding. A company operating as Darwin Freight Logistics and Transport, for example, is signalling to clients that they offer a turnkey solution: they don’t just provide the truck (transport); they also handle the route planning, storage, and complex supply chain coordination (logistics).

What is Transport? (The Muscle)

Transport (or transportation) is the physical act of moving people, goods, and animals from one location to another. It is the tactical execution of the supply chain. Without transport, the best logistics plan in the world is just a piece of paper.

The Main Modes of Transport

To be effective, transport managers must choose the right mode based on cost, speed, and the type of goods.

- Road Transport: The most common form of transport for “last-mile” delivery. It offers high flexibility and door-to-door service but is limited by capacity and traffic. While commercial fleets operate on a massive scale, the principles of safe transport apply even to individual vehicles. Understanding regulations, such as how to manage towing weights and road safety limits, is critical whether you are hauling a shipping container or a recreational caravan.

- Rail Transport: Ideal for heavy, bulky goods (coal, steel, grain) moving over long distances. It is cost-effective and eco-friendly, but lacks flexibility.

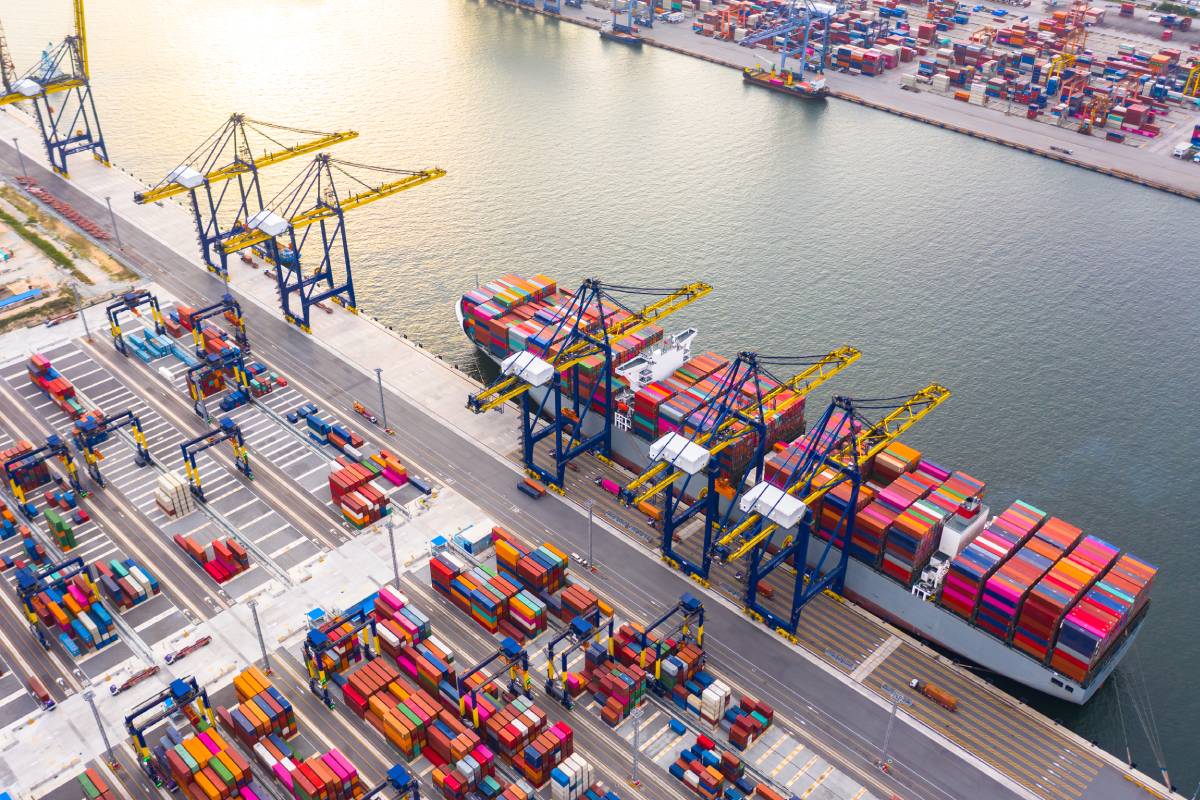

- Maritime (Sea) Transport: The backbone of international trade. Roughly 90% of the world’s goods are transported by sea. It is the cheapest method for high volume, but the slowest.

- Air Transport: The fastest mode, used for high-value or perishable goods (electronics, flowers, pharmaceuticals). It is the most expensive option.

- Pipeline Transport: Specifically for liquids and gases (oil, water, natural gas). It offers continuous flow but has a high initial infrastructure cost.

What is Logistics? (The Brain)

Logistics is a broader concept that falls under the umbrella of Supply Chain Management (SCM). It involves the planning, implementation, and control of the efficient flow and storage of goods, services, and information.

Logistics is about optimization. A logistics manager asks: How do we get this product to the customer faster, cheaper, and with fewer errors?

Key Functions of Logistics:

- Order Processing: Handling the workflow from the moment a customer clicks “buy” to delivery.

- Inventory Management: Balancing stock levels to ensure you have enough to sell without paying too much for storage.

- Warehousing: The safe storage and organization of goods. Effective warehousing isn’t just about storage space; it’s about accessibility. Logistics managers must constantly ensure safety and efficiency during the loading process, which often involves precise calculations like determining the load capacity of loading ramps to prevent bottlenecks or accidents.

- Packaging: Ensuring goods are packed to withstand transport and minimize wasted space.

- Information Flow: Tracking data (using barcodes, RFID, GPS) to know where items are in real-time.

The 7 Rs of Logistics

To truly understand the goal of logistics, industry professionals refer to the “7 Rs.” This concept was popularized by the Chartered Institute of Logistics and Transport.

Logistics is about getting the:

- Right Product

- In the Right Quantity

- In the Right Condition

- At the Right Place

- At the Right Time

- To the Right Customer

- At the Right Price

If any of these “Rs” fail (e.g., the product arrives on time but is damaged), the logistics process has failed.

Key Differences at a Glance

For a quick reference, here is how the two concepts compare:

| Feature | Transport | Logistics |

| Primary Focus | Movement of goods. | Management of the flow of goods. |

| Scope | Narrow (A specific activity). | Broad (Includes transport, storage, planning). |

| Technology | Vehicles, ships, aircraft, trucks. | WMS (Warehouse Mgmt Systems), AI, ERP software. |

| Objective | Delivery from A to B. | Customer satisfaction and cost efficiency. |

| Relationship | A subset of logistics. | A subset of Supply Chain Management. |

How They Work Together: A Real-World Example

Let’s look at the journey of a smartphone to see how logistics and transport intertwine.

- Sourcing (Logistics): The phone manufacturer forecasts demand and orders components (screens, chips, batteries) from suppliers in Korea, Taiwan, and the US.

- Inbound Transport: These components are shipped via Air Transport to a factory in China for assembly.

- Warehousing (Logistics): The finished phones are stored in a climate-controlled warehouse. Inventory systems track every unit.

- Distribution Planning (Logistics): Orders come in from retailers in Europe. The logistics team creates a shipping schedule to consolidate orders into one container to save money.

- Outbound Transport: The container is loaded onto a truck (Road), then a ship (Sea), and finally a train (Rail) to reach a distribution center in Germany.

- Last Mile (Transport): A courier van (Road) delivers the specific box to the electronics store.

Without transport, the phone stays in the factory. Without logistics, the components never arrive at the factory in the first place, or the wrong phone arrives at the wrong store.

The Future of Logistics and Transport

The industry is currently undergoing a massive transformation, often called Logistics 4.0.

- Automation and AI: Warehouses are increasingly using autonomous robots for picking and packing. AI predicts demand spikes before they happen.

- Green Logistics: With a focus on sustainability, companies are optimizing routes to reduce fuel consumption and investing in electric delivery fleets.

- Blockchain: This technology provides transparent, tamper-proof records of a product’s journey, increasing trust and security.

Conclusion

So, what is logistics and transport? They are the symbiotic forces that drive the modern world. Transport provides the wheels, wings, and hulls to move the world’s wealth, while logistics provides the intelligence to ensure that movement is efficient, profitable, and reliable.

Whether you are looking to optimize a business or simply understand how your package arrived overnight, recognizing the interplay between these two fields is the first step toward mastering the supply chain.